Description

INTRODUCE

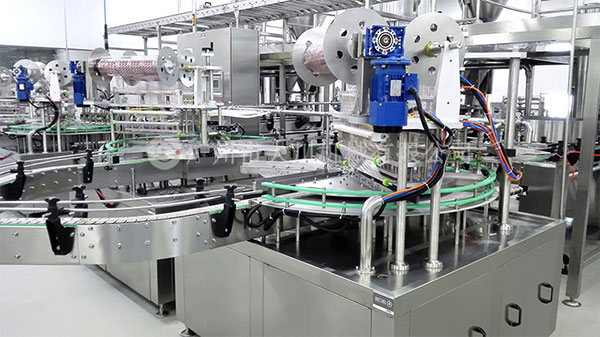

This equipment is our company according to many years of experience in research and development, has the sauce filling and sealing the unity of two functions all-in-one, intermittent rotary transfer mechanism to the bottle to the filling station infusion fluids, first filling to bottles of juice changes over dry in the bottle, and ultimately to ensure that each bottle of product level distance is consistent with the position of the bottle, juice after completion of filling, sealing wheel would carry the bottle to the sealing station. Using plastic heat sealing, the sealing of die cutting, sealing on the principle of heat sealing type, designed specifically for plastic bottle seal, the sealing is strong, beautiful, low consumables and anticorrosion sealing machine.

PERFORMANCE CHARACTERISTICS

●Equipment adopts filling juice sealing structure, cover an area of an area small, is suitable for the need to add liquid product;

●Pour juice system can form a complete set of our research and development of automatic mixing system used together;

●With automatic detection fault point system, if the equipment is abnormal, will trigger the alarm system, touch screen prompt alarm abnormal points, convenient operation staff troubleshooting;

●Can production according to the customer request custom different seal Numbers and filling head count.

Technical Parameters

| Power supply voltage | AC380V/50HZ |

| Gas pressure | 0.6-0.8Mpa/0.1m3/min |

| Work rate | 2600W |

| Sealing speed | 2500 bottles / h |

| Sealing temperature | 50-300 ℃ (adjustable) |

| Sealing range | Φ70-Φ250mm |

| Constant temperature forms and deviation | utomatic constant temperature, deviation ±3℃ |

| Pour juice range | 10mL-500mL |

| Overall dimensions | 2000×1600×1800mm |

| Heavy volume | 740kg |

Reference map